Please note that product indicated below are purely for display purposes. Most of the products we offer come in an assortment of colours - when doing an enquiry, please specify the colours you desire and we will get back to you to confirm.

Please note that product indicated below are purely for display purposes. Most of the products we offer come in an assortment of colours - when doing an enquiry, please specify the colours you desire and we will get back to you to confirm.

An analyzer is a tool used to analyze data. For example, a gas analyzer tool is used to analyze gases. It examines the given data and tries to find patterns and relationships. An analyser can be a piece of hardware or software. Autoanalysers perform their work with little human involvement. Analysis can be done directly on samples or the analyser can process data acquired from a remote sensor. The source of samples for automatic sampling is commonly some kind of industrial process. Analysers that are connected to a process and conduct automatic sampling, can be called online (or on-line) analysers or sometimes inline (or in-line) analysers. For inline analysis, a sensor can be placed in a process vessel or stream of flowing material. Another method of online analysis is allowing a sample stream to flow from the process equipment into an analyser, sometimes conditioning the sample stream e.g., by reducing pressure or changing the sample temperature. Many analysers are not designed to withstand high pressure. Such sampling is typically for fluids (either liquids or gases). If the sample stream is not substantially modified by the analyser, it can be returned to the process. Otherwise, the sample stream is discarded; for example, if reagents were added.

An electrical cable is an assembly of one or more wires running side by side or bundled, which is used to carry electric current. A cable assembly is the composition of one or more electrical cables and their corresponding connectors.

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and SCADA systems. They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory.

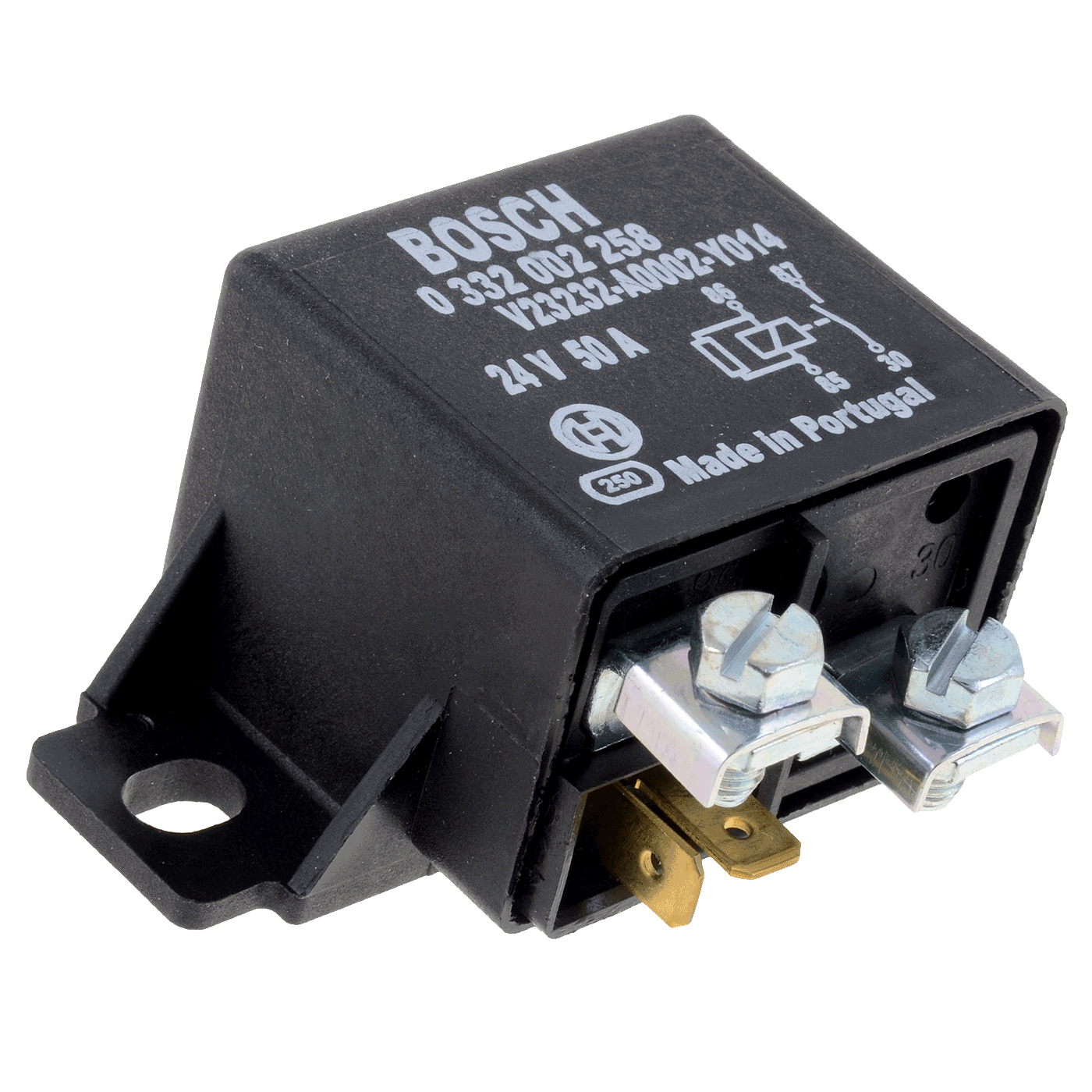

A relay is an electrically operated switch. It consists of a set of input terminals for a single or multiple control signals, and a set of operating contact terminals. The switch may have any number of contacts in multiple contact forms, such as make contacts, break contacts, or combinations thereof. Relays are used where it is necessary to control a circuit by an independent low-power signal, or where several circuits must be controlled by one signal. Relays were first used in long-distance telegraph circuits as signal repeaters: they refresh the signal coming in from one circuit by transmitting it on another circuit. Relays were used extensively in telephone exchanges and early computers to perform logical operations.

A sensor is a device that produces an output signal for the purpose of sensing of a physical phenomenon. In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends the information to other electronics, frequently a computer processor. Sensors are always used with other electronics. Analog sensors such as potentiometers and force-sensing resistors are still widely used. Their applications include manufacturing and machinery, airplanes and aerospace, cars, medicine, robotics and many other aspects of our day-to-day life. There is a wide range of other sensors that measure chemical and physical properties of materials, including optical sensors for refractive index measurement, vibrational sensors for fluid viscosity measurement, and electro-chemical sensors for monitoring pH of fluids. A sensor's sensitivity indicates how much its output changes when the input quantity it measures changes.

In electrical engineering, a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another. The most common type of switch is an electromechanical device consisting of one or more sets of movable electrical contacts connected to external circuits. When a pair of contacts is touching current can pass between them, while when the contacts are separated no current can flow. Switches are made in many different configurations; they may have multiple sets of contacts controlled by the same knob or actuator, and the contacts may operate simultaneously, sequentially, or alternately. A switch may be operated manually, for example, a light switch or a keyboard button, or may function as a sensing element to sense the position of a machine part, liquid level, pressure, or temperature, such as a thermostat. Many specialized forms exist, such as the toggle switch, rotary switch, mercury switch, push-button switch, reversing switch, relay, and circuit breaker. A common use is control of lighting, where multiple switches may be wired into one circuit to allow convenient control of light fixtures. Switches in high-powered circuits must have special construction to prevent destructive arcing when they are opened.

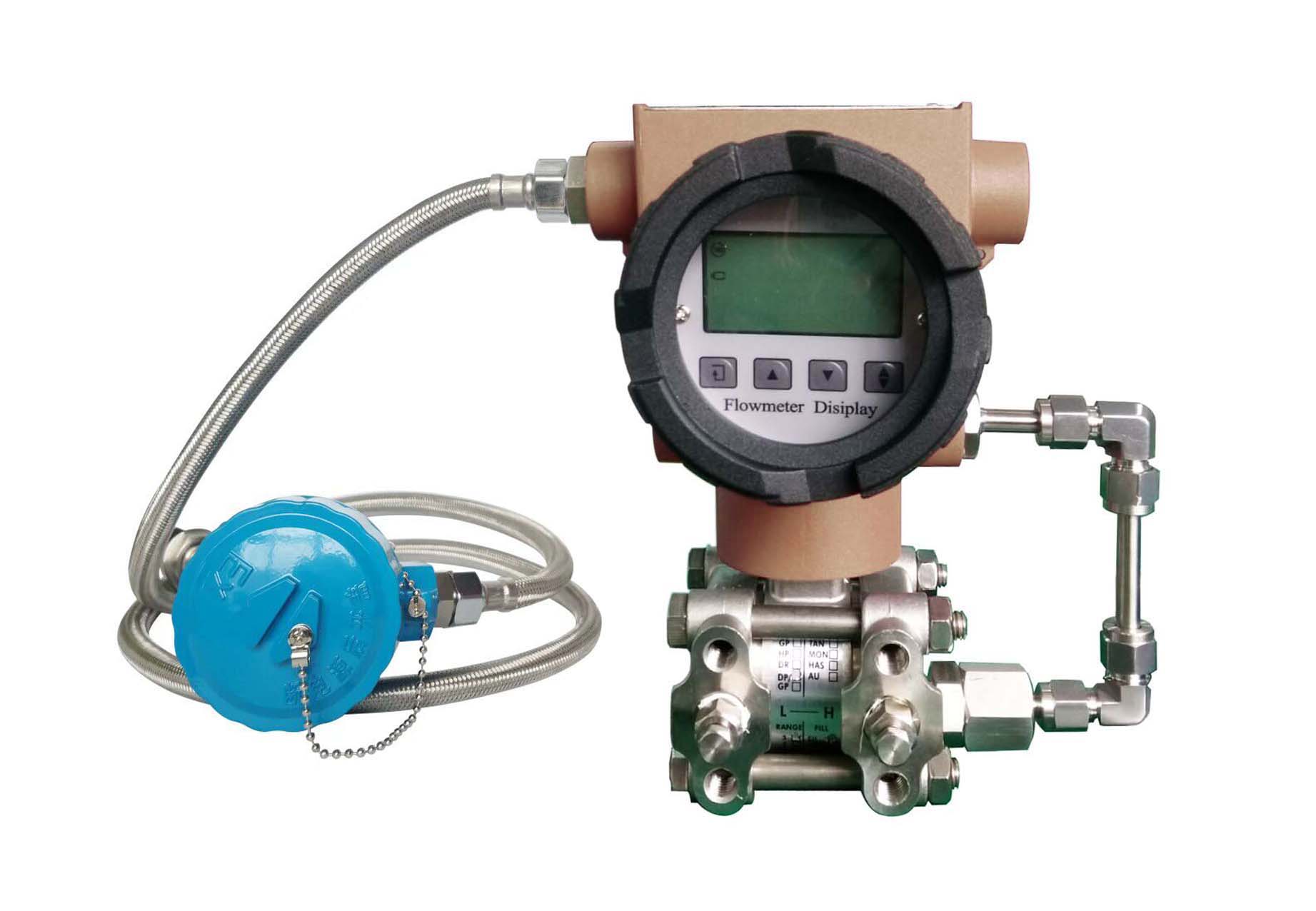

The design of the electronic DP transmitter is based on differential capacitance. The sensing element is a taut metal diaphragm located between two stationary metal surfaces, comprising three plates for a complimentary pair of capacitors. An electrically insulating fill fluid (usually a liquid silicone compound) transfers motion from the isolating diaphragms to the sensing diaphragm and also doubles as an effective dielectric for the two capacitors.

A circuit breaker is an electrical safety device designed to protect an electrical circuit from damage caused by an overcurrent or short circuit. Its basic function is to interrupt current flow to protect equipment and to prevent the risk of fire. Unlike a fuse, which operates once and then must be replaced, a circuit breaker can be reset (either manually or automatically) to resume normal operation. Circuit breakers are made in varying sizes, from small devices that protect low-current circuits or individual household appliance, up to large switchgear designed to protect high voltage circuits feeding an entire city. The generic function of a circuit breaker, or fuse, as an automatic means of removing power from a faulty system is often abbreviated as OCPD (Over Current Protection Device). a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another. The most common type of switch is an electromechanical device consisting of one or more sets of movable electrical contacts connected to external circuits. When a pair of contacts is touching current can pass between them, while when the contacts are separated no current can flow. Switches are made in many different configurations; they may have multiple sets of contacts controlled by the same knob or actuator, and the contacts may operate simultaneously, sequentially, or alternately. A switch may be operated manually, for example, a light switch or a keyboard button, or may function as a sensing element to sense the position of a machine part, liquid level, pressure, or temperature, such as a thermostat. Many specialized forms exist, such as the toggle switch, rotary switch, mercury switch, push-button switch, reversing switch, relay, and circuit breaker. A common use is control of lighting, where multiple switches may be wired into one circuit to allow convenient control of light fixtures. Switches in high-powered circuits must have special construction to prevent destructive arcing when they are opened.

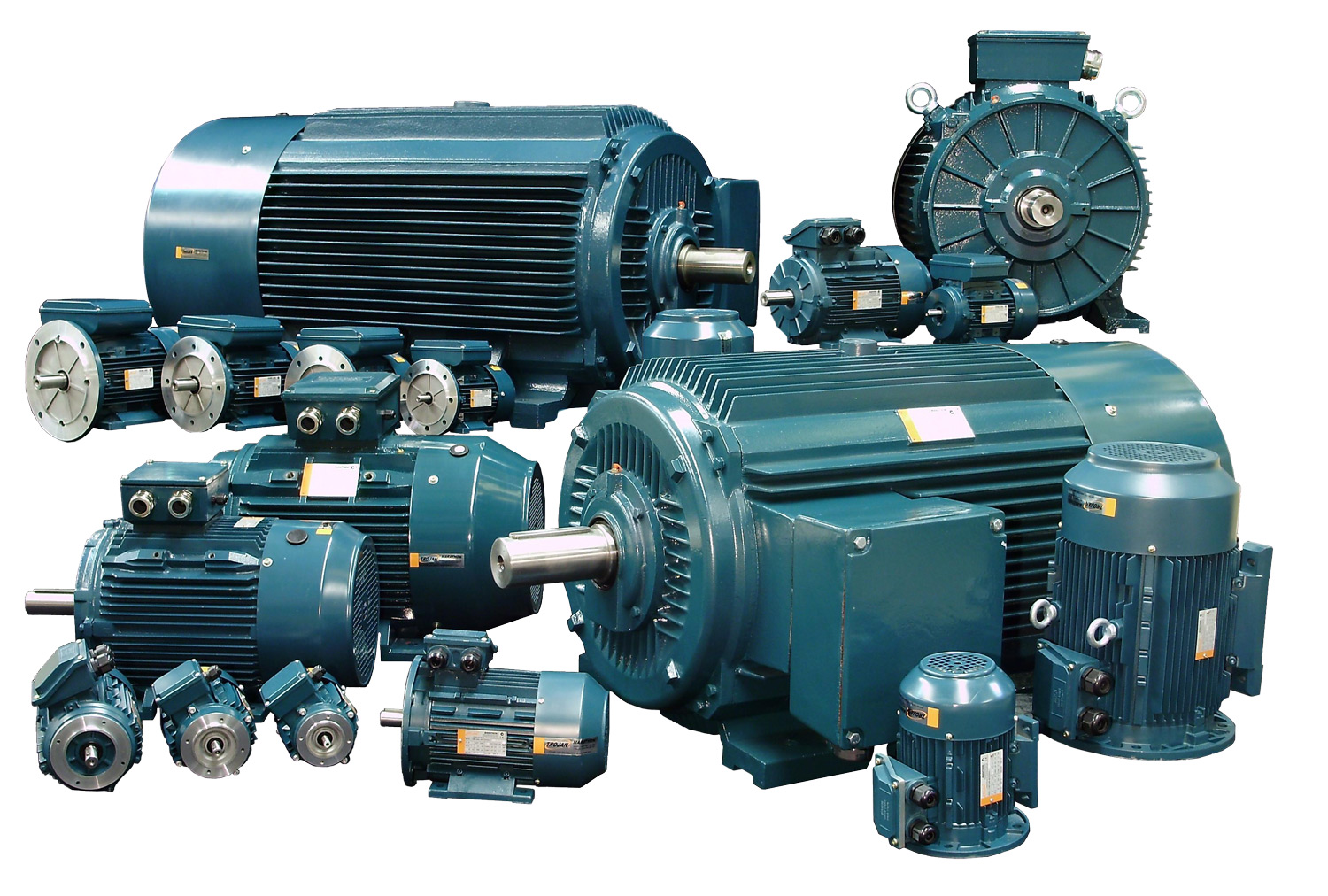

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. Electric motors can be powered by direct current (DC) sources, such as from batteries, or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy. Electric motors may be classified by considerations such as power source type, internal construction, application and type of motion output. In addition to AC versus DC types, motors may be brushed or brushless, may be of various phase (see single-phase, two-phase, or three-phase), and may be either air-cooled or liquid-cooled.

A transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple circuits. A varying current in any one coil of the transformer produces a varying magnetic flux in the transformer's core, which induces a varying electromotive force across any other coils wound around the same core. Electrical energy can be transferred between separate coils without a metallic (conductive) connection between the two circuits. Transformers are most commonly used for increasing low AC voltages at high current (a step-up transformer) or decreasing high AC voltages at low current (a step-down transformer) in electric power applications, and for coupling the stages of signal-processing circuits. Transformers can also be used for isolation, where the voltage in equals the voltage out, with separate coils not electrically bonded to one another. Transformers have become essential for the transmission, distribution, and utilization of alternating current electric power. A wide range of transformer designs is encountered in electronic and electric power applications. Transformers range in size from RF transformers less than a cubic centimeter in volume, to units weighing hundreds of tons used to interconnect the power grid.

Motor drive means a system that includes a motor. An adjustable speed motor drive means a system that includes a motor that has multiple operating speeds. A variable speed motor drive is a system that includes a motor and is continuously variable in speed. If the motor is generating electrical energy rather than using it – this could be called a generator drive but is often still referred to as a motor drive. Sometimes this is confused with a Variable Frequency Drive(VFD) or Variable Speed Drive(VSD) which describes the electronic portion of the system that controls the speed of the motor. More generally, the term drive, describes equipment used to control the speed of machinery. Many industrial processes such as assembly lines must operate at different speeds for different products. Where process conditions demand adjustment of flow from a pump or fan, varying the speed of the drive may save energy compared with other techniques for flow control. Where speeds may be selected from several different pre-set ranges, usually the drive is said to be adjustable speed. If the output speed can be changed without steps over a range, the drive is usually referred to as variable speed. Adjustable and variable speed drives may be purely mechanical (termed variators), electromechanical, hydraulic, or electronic. Sometimes motor drive refers to a drive used to control a motor and therefore gets interchanged with VFD or VSD.

Metal bellows are vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape, provided the material has not been stressed past its yield strength. They are used both for their ability to deform under pressure and to provide a hermetic seal that allows movement.

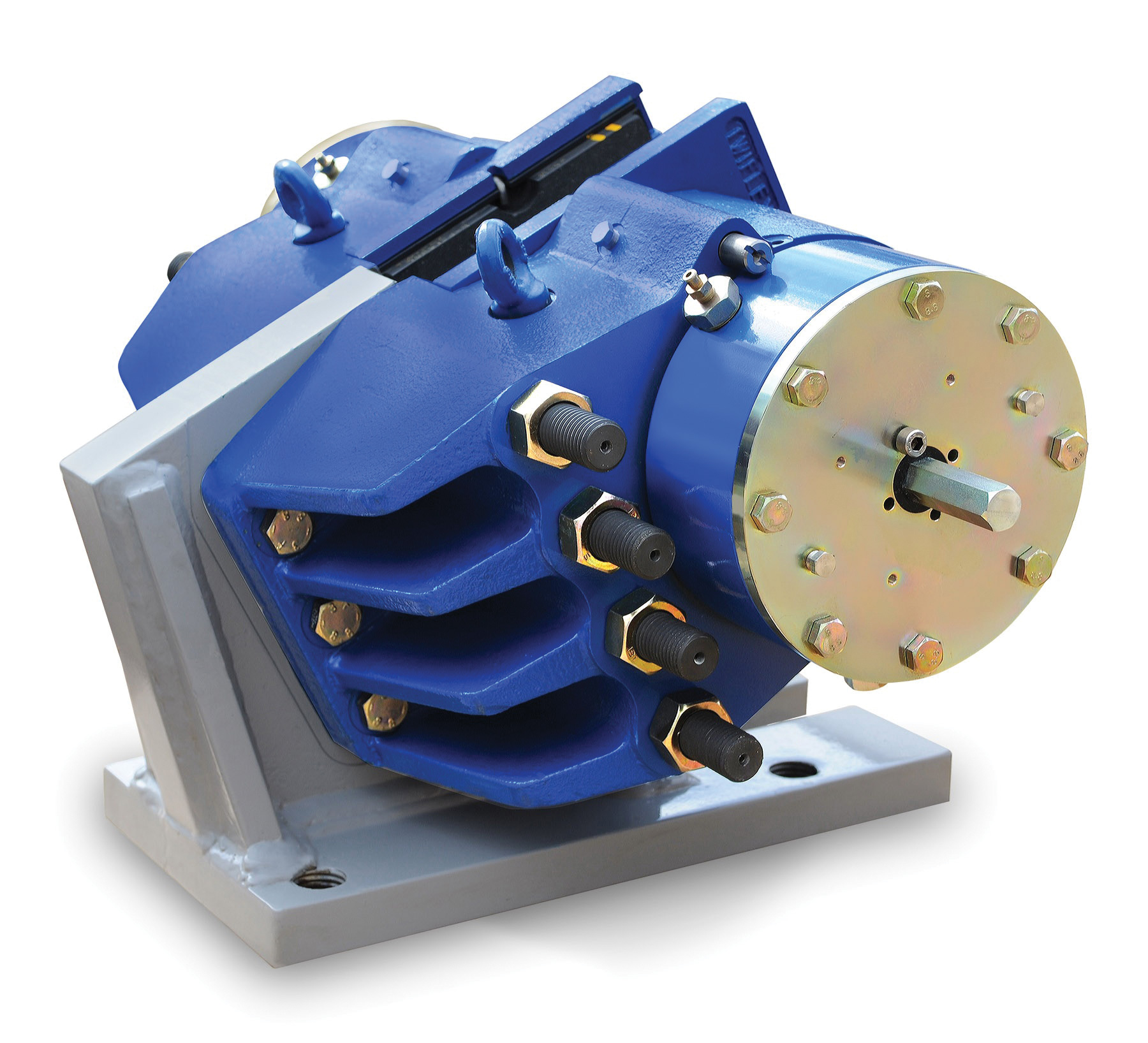

A clutch is a mechanical device that engages and disengages power transmission, especially from a drive shaft (driving shaft) to a driven shaft.In the simplest application, clutches connect and disconnect two rotating shafts (drive shafts or line shafts). In these devices, one shaft is typically attached to an engine and other to power unit (the driving member), while the other shaft (the driven member) provides output power for work.

Mechanically, a fan can be any revolving vane, or vanes used for producing currents of air. Fans produce air flows with high volume and low pressure (although higher than ambient pressure), as opposed to compressors which produce high pressures at a comparatively low volume. A fan blade will often rotate when exposed to an air-fluid stream, and devices that take advantage of this, such as anemometers and wind turbines, often have designs similar to that of a fan.

Fuel filters serve a vital function in today's modern, tight-tolerance engine fuel systems. Unfiltered fuel may contain several kinds of contamination, for example paint chips and dirt that has been knocked into the tank while filling, or rust caused by moisture in a steel tank. If these substances are not removed before the fuel enters the system, they will cause rapid wear and failure of the fuel pump and injectors, due to the abrasive action of the particles on the high-precision components used in modern injection systems. Fuel filters also improve performance, as the fewer contaminants present in the fuel, the more efficiently it can be burnt. Some filters, especially found on diesel engines, are of a bowl-like design which collect water in the bottom (as water is more dense than diesel). The water can then be drained off by opening a valve in the bottom of the bowl and letting it run out, until the bowl contains only diesel. Many diesel fuel filters contain a water sensor to signal to the engine control unit or directly to the driver if the water reaches the warning level. It is especially undesirable for water in fuel to be drawn into a diesel engine fuel system, as the system relies on the diesel for lubrication of the moving parts, and if water gets into a moving part which requires constant lubrication (for example an injector valve), it will quickly cause overheating and unnecessary wear. This type of filter may also include a sensor, which will alert the operator when the filter needs to be drained. In proximity to the diesel fuel filter there might be a fuel heater to avoid the forming of paraffin wax (in case of low temperatures) inside the filtrating element which can stop the fuel flow to the engine.

The term transmission properly refers to the whole drivetrain, including clutch, gearbox, prop shaft (for rear-wheel drive vehicles), differential, and final drive shafts. In the United States the term is sometimes used in casual speech to refer more specifically to the gearbox alone, and detailed usage differs. Conventional gear/belt transmissions are not the only mechanism for speed/torque adaptation. Alternative mechanisms include torque converters and power transformation (e.g. diesel-electric transmission and hydraulic drive system). Hybrid configurations also exist. Automatic transmissions use a valve body to shift gears using fluid pressures in response to engine RPM, speed, and throttle input.

Hydrocyclones are of cyclonic separators that separating product phases mainly on basis of differences in gravity with aqueous solutions as the primary feed fluid. As opposed to dry or dust cyclones, which separate solids from gasses, hydrocyclones separate solids or different phase fluids from the bulk fluid. A hydrocyclone comprises a cylindrical shaped feed part with tangential feed; an overflow part with vortex finder; a conical part with an apex. A cyclone has no moving parts. Product is fed into the hydrocyclone tangentially under a certain pressure. This creates a centrifugal movement, pushing the heavier phase outward and downward alongside the wall of the conical part. The decreasing diameter in the conical part increases the speed and so enhances the separation. Finally, the concentrated solids are discharged through the apex. The vortex finder in the overflow part creates a fast rotating upward spiral movement of the fluid in the centre of the conically shaped housing. The fluid is discharged through the overflow outlet.

Electromagnetic brakes (also called electro-mechanical brakes or EM brakes) slow or stop motion using electromagnetic force to apply mechanical resistance (friction). Both electromagnetic brakes and eddy current brakes use electromagnetic force, but electromagnetic brakes ultimately depend on friction whereas eddy current brakes use magnetic force directly.

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: direct lift, displacement, and gravity pumps. Pumps operate by some mechanism (typically reciprocating or rotary), and consume energy to perform mechanical work moving the fluid. Pumps operate via many energy sources, including manual operation, electricity, engines, or wind power, and come in many sizes, from microscopic for use in medical applications, to large industrial pumps. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems.

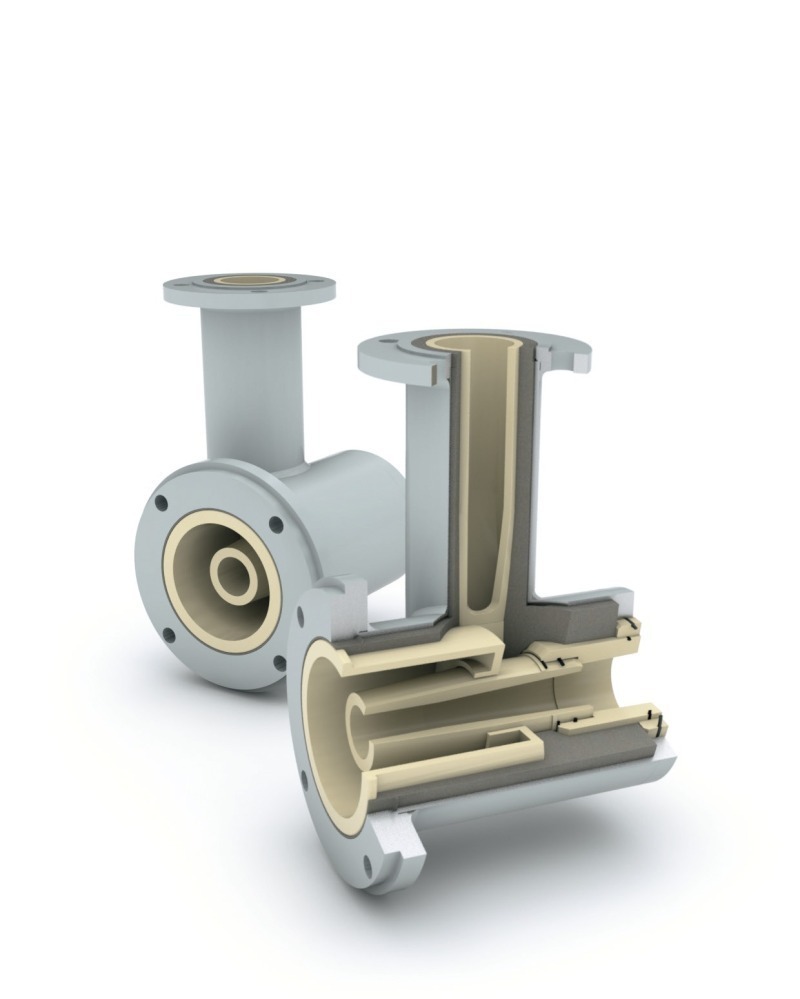

A mechanical seal is a device that helps join systems or mechanisms together by preventing leakage (e.g. in a pumping system), containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets. The seals are installed in pumps in a wide range of industries including chemicals, water supply, paper production, food processing and many other applications. A stationary seal may also be referred to as 'packing'.

A mechanical filter device to catch or collect debris.

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating (or measuring) fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes.